If you are just beginning woodworking, you may have asked yourself the question, “Do I really need a wood router?”. I know I asked myself this question a lot as I started this hobby, and it took me a while to answer this myself. My goal is that with this article, we will shed some light on this question and be able to help you determine if this is a tool you should invest in.

The short answer is this; it depends. A wood router is a valuable tool for most woodworkers today. They are versatile tools, and although they are not required for woodworking, they can make your life much easier. Any furniture, inlays, or trim work, and a router will become a go-to tool. They are highly capable of making cuts inside your workpiece, applying a decorative edge, or creating a wide variety of joints.

I know this is not the answer you wanted, but hopefully, we can break down a few different factors that can help you make your decision.

What Type of Cuts Can I Make with a Router?

One of the main deciding factors you should ask yourself is, “what type of cuts do I plan on making?” Depending on the type of cuts you will be making in your workpiece, this can help you determine if a router would be a beneficial purchase. I have searched the web and gathered up some information on the top cuts people use a router for.

Chamfered Edge

A chamfered edge (also referred to as a beveled edge), is a transitional edge between two faces of an object. One of the most common chamfers is a 45-degree cut between two perpendicular faces. A chamfered edge can serve a few purposes. It is a good way to knock off a sharp edge created by perpendicular faces. It can also give your workpiece a decorative-looking edge, and enhance the overall appearance of your project. Chamfered edges can be achieved without using a router, but a chamfered router bit with a guide bearing makes the whole process very easy and looks great after you have finished.

Rounded Edge

Another popular edge treatment is the rounded edge. This is achieved with a router roundover bit. Instead of applying a straight edge at an angle like the chamfered bit; a roundover bit applies a radius to the edge of the workpiece. This gives your project a nice finished look and eliminates any sharp edges associated with having two perpendicular faces. A roundover bit can have a few different variations and can be quite versatile for applying decorative cuts and enhancing the look and feel of your project.

Straight Cuts

The straight cut is a very popular cut for routers. The ability to change your depth and also cut inside of a workpiece can be pretty useful for several different projects. A straight cut is made using a straight bit (real surprise there). These bits can cut square-shaped grooves in a workpiece. This allows you to cut grooves and dados. These types of cuts are useful for creating some joinery methods such as a mortise and tenon joint. They can also be used for inlays or custom designs inside a workpiece.

Rabbet Cuts

A rabbet cut is a groove cut on the edge of a workpiece, which can allow boards to be recessed or can be added to help strengthen a joint more than a butt joint alone. A router can allow you to precisely cut rabbet joints quickly and efficiently. It is a very common joining method in cabinets and has a ton of useful scenarios.

Dovetail Joints

A dovetail joint is a technique that consists of creating two parts that interweave. This technique produces an extremely strong joint with high tensile strength. Typically with this joint, other fasteners are not needed as long as the joint is glued. Dovetail joints are fairly common when building and assembling drawers, but have many other uses. The good thing about these joints is that there are dovetail templates that allow a router to be used for this technique. With the templates and router, this joinery method becomes much easier to utilize, and can really enhance your project.

Do I Need a Router Table?

Another question you may have already been contemplating is, “Do I need a router table?”. The short answer is no. This does not mean you shouldn’t get one, it just means that a router can and will work without a router table. It is perfectly acceptable to have a solid means of clamping your workpiece and then moving the router to make the cuts you need. However, you should invest in a router table if you can afford it. There are a few really good benefits to having an actual router table to pair with your router.

- Precision. With a router table, you can precisely set the height of the bit, set the fence, and tune every piece of your setup until you dial in the perfect settings. Once these settings are set, all that you have to do is move the workpiece across the bit.

- Different types of cuts. A router table enables you to significantly expand the type of cuts you can make. You can expand into grooves, slots, stopped cuts, and more. If you are wanting to start making dovetail joints, a router table is a necessary addition to your router.

- Consistency. As discussed already, with a router table, you can have everything dialed in to fit your needs exactly. Another benefit of this is consistency. You can run board after board on the same settings and get extremely consistent results.

What Type of Wood Routers Are Available?

When looking into what wood router may best suit your needs, it’s important to understand the types of routers available. Luckily, there aren’t many differences in the type of routers that you can have, but we will dive into the two types you may encounter.

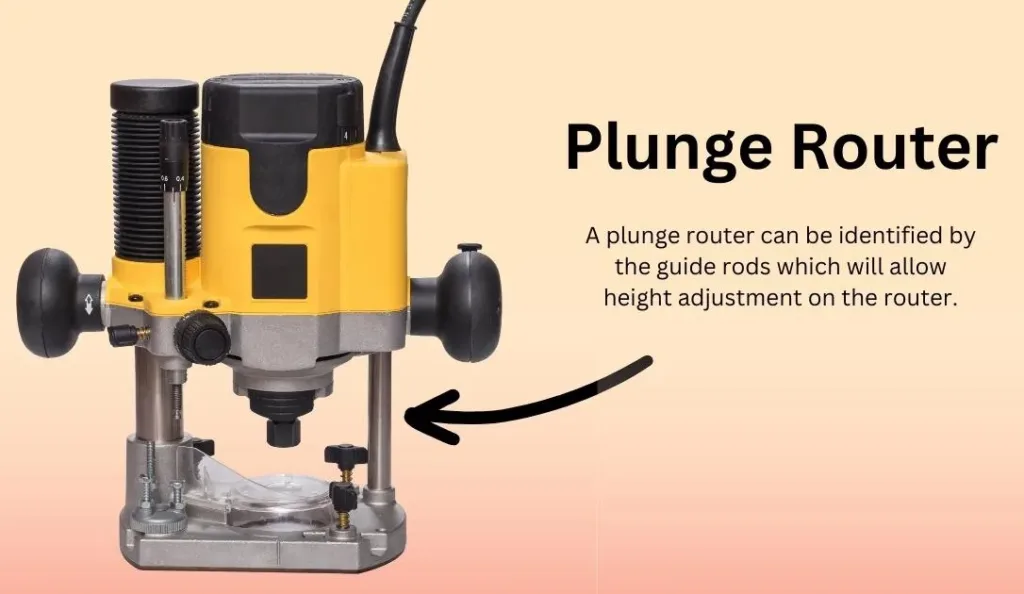

Plunge Router

Plunge routers are designed so that they can be, you guessed it, plunged into the workpiece. The router travels up and down on spring-loaded rods. The advantage of this type of router is how quickly you can have the depth of cut adjusted. You move the router over your workpiece, and then move it to the correct depth and start cutting. This depth is easy to adjust on the fly, making quick work of whatever cuts you are trying to make. These routers are a great option if you will be making any cuts inside a workpiece.

Fixed Base Router

The fixed base router differs from the plunge router in how the depth of cut is adjusted. The depth of cut can be adjusted more precisely, but not as quickly. Once the height is set, it can be locked in. A fixed base router is well suited for edge work on a workpiece due to its consistent height.