When I first started my woodworking hobby, I invested in a table saw early on. It is an extremely versatile tool, but at the time I didn’t know a whole lot about them. I just watched some videos and jumped right into it. However, there is a question that I am sure a lot of people have probably wondered at some point, myself included, especially when it comes to picking up a new blade for the table saw. The question is just how many teeth should your table saw blade have?

In general, a table saw blade should have 20 to 40 teeth for rip cuts, 40 to 60 teeth for general purpose (rip cuts and cross cuts), and 60 – 80 teeth for cross-cutting. The lower tooth count for ripping boards allows for proper chip removal, while a higher tooth count for cross-cutting boards helps prevent tear-out.

The number of teeth you need for your table saw blade will vary depending on the type of work you are doing. Keep reading as we look deeper into how to choose the right blade for you.

How many teeth is best for cutting wood?

The number of teeth you need to have on your table saw blade for cutting wood will vary depending on the type of cut you are performing and also the type of material you are cutting. There are however some general guidelines when it comes to choosing a table saw blade that you can follow.

If you will be ripping a board, or cutting along the grain of a board, you will want to use a blade with 40 teeth or less.

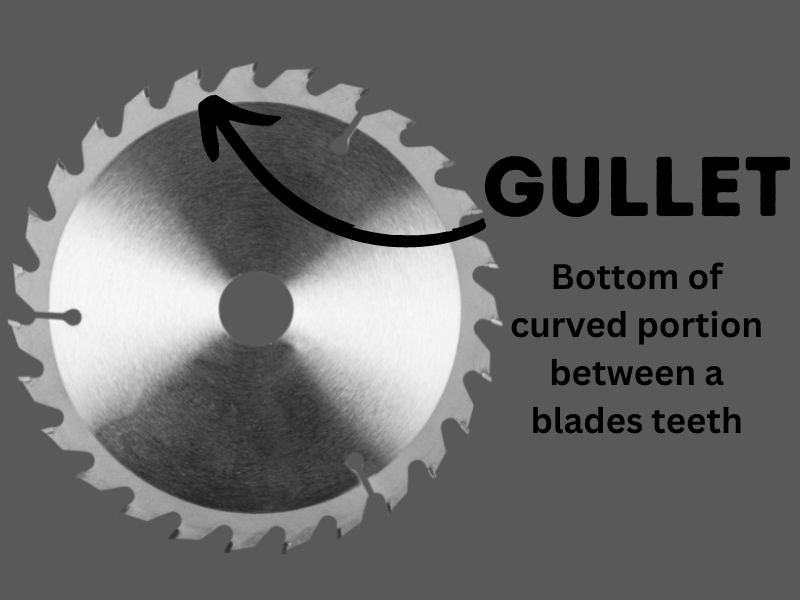

The reason for this is that when you cut with the grain, the chips tend to be longer and need extra space between teeth to clear the chips and avoid overheating. This extra space is called a gullet and you will read more about that in another section below.

When you will be cross-cutting a board or cutting against the grain, you will want to use a blade with 60 teeth or more.

The reason for more teeth when cross-cutting is that with fewer teeth, you will cut more aggressively with each pass of the blade, and this can cause tear out. In general, the more teeth you have on your blade, the smoother the result will be.

If you want to have a blade capable of both cross-cutting and ripping, a 40 to 60-tooth combination blade will work. However, the cuts won’t be as clean as they would be with a dedicated blade.

A combination blade won’t particularly excel at cross-cutting or ripping, but it can perform both decently. If you were going to only have one blade this would be the one to invest in.

Are more teeth on a table saw blade better?

Are more teeth on a table saw better? This is a common misconception, but I can see where it would come from. It would just seem to make sense that if you had more teeth to cut, it would perform better. However, this is only partially true.

When you cut with the grain of the wood, the chips are naturally much longer than if you were cutting against the grain of the wood. With longer chips, they need a way to be cleared from the blade before the next tooth comes along and makes another chip.

If the wood chips don’t clear well, there will be a buildup of material, and a buildup of heat. This is not good for your blade and not good for the board. It can cause burning on the surface of the wood which is a problem most people try to avoid.

Now that we have why it is not always true out of the way, we can talk about when it is true. When you are cross-cutting a board you are going against the natural direction of the wood. The chips you create will be much smaller than when ripping a board and will also tend to want to cause tear out. Not good.

The solution to this? More teeth. More teeth will mean a smaller gap between teeth and will mean that each tooth will only remove a small chip of wood with each pass. This significantly reduces tear-out and can leave you with a nice, smooth surface.

What Other factors should you look at when choosing a blade for your table saw

At this point, you should have a pretty good idea of which tooth count you need in a table saw blade and the reason behind it. Now on to a few things to also be on the lookout for when choosing a table saw blade. Besides tooth count, what other factors should you be looking at when choosing a blade?

The other factors besides tooth count that should be taken into consideration when choosing a table saw blade are gullets and tooth geometry. These will affect how well the chips clear the blade and how aggressive the material removal is.

Gullet

The gullet on a saw blade is the curved surface at the bottom of the gap between the teeth. When a blade slices through a board, the material that is removed will need somewhere to go to allow the next tooth to cut properly. This is where the gullet comes in.

When you are cutting with the grain of the wood, the chips are much longer than when cross-cutting and therefore need more space to clear out properly. This is why a smaller tooth count when ripping a board is important, as well as a large gullet. This will give ample space for the larger chips to clear. If they don’t have space to clear it can lead to buildup which will cause overheating and burning of the wood.

Cross-cutting a board produces much smaller chips than when ripping a board and because of this, can operate normally with a much smaller gullet, and higher tooth count.

Tooth Geometry

Another thing to look for when choosing a blade is tooth geometry. This can refer to a few things but we will be talking about tooth design. The four main tooth designs are flat top grind (FTG), Alternate Top Bevel (ATB), Combination (ATBR), and Triple Chip Grind (TCG)

Flat Top Grind (FTG): FTG teeth are flat at the top cutting surface and work well for ripping boards. They will make ripping a board faster and cleaner than some of the alternatives.

Alternate Top Bevel (ATB): ATB teeth are angled, alternating between cutting points. This type of tooth design can work well for making cross cuts cleanly.

Combination (ATBR): ATBR teeth are a combination of FTG and ATB teeth. Hence, the name combination blade.

Triple Chip Grind (TCG): TCG teeth feature a flat top tooth and then a tooth with a flat top but the corners are removed, and these alternate throughout the blade. These can be useful with materials such as plywood veneers, MDF, and melamine.

General Purpose Blade: A general purpose blade uses the ATB tooth design so it works well for cross cuts but it uses fewer teeth than a dedicated FTG blade. This allows the same blade to also be used for ripping a board with decent results. If you were to just have one top-notch blade, this would be the one you should get.

Final Thoughts

When choosing a blade for your table saw, you may want to consider things like the type of projects you plan to take on as well as what your budget may be. If you have the funds, dedicated cross-cut, and ripping blades are a better option. However, if you are on a budget and only have the funds for one good blade, I would recommend getting a general-purpose blade that can be used on just about every project with decent results.