If you have ever made cuts with your table saw but were less than satisfied with the results because you couldn’t get straight cuts, you are not alone. I am sure a ton of people have dealt with this issue at one time or another, including myself. To help solve this problem, I turned to Google and began searching for what was causing the issue and how to fix it. I was able to find some common causes of a table saw failing to cut straight.

The most common causes of a table saw not cutting straight are:

- Incorrect alignment of the blade, fence, miter gauge, miter gauge slots, or a combination of these.

- A warped or loose blade.

- A damaged or dirty blade.

- Incorrect feeding of the wood through the table saw.

As I looked into these issues, I gathered some details on each of the causes and how to fix them. Keep reading below as we look further into this and hopefully give you the information you need to help you fix your table saw blade not cutting straight.

Checking Table Saw Alignment

Checking the alignment of multiple points on your table saw is an imperative skill. Without having everything aligned correctly, you will never be able to achieve a high level of fine woodworking. But don’t fret, we will dive into the items you need to check to get your table saw up to par for some great woodworking projects.

Quick Tip: To perform these measurements, it is recommended to use a high-quality square. A speed square can work but something a little more precise is recommended. The measurements will only be as good as your measuring equipment. You can get a decent square for $20 or $30 bucks. My favorite to use is machinist squares, which you can find on amazon for under 30 dollars.

Blade Alignment

The first item to check will be your blade’s alignment with your table saws table. All table saws will have markings that let you know what angle it is set at, but if you have issues as I did, the numbers on the dial may be wrong.

Using a square, check that the blade and the table are perfectly at 90 degrees. If they are out of alignment, use the adjustment on your table saw to move the blade until it sits at 90 degrees to your table.

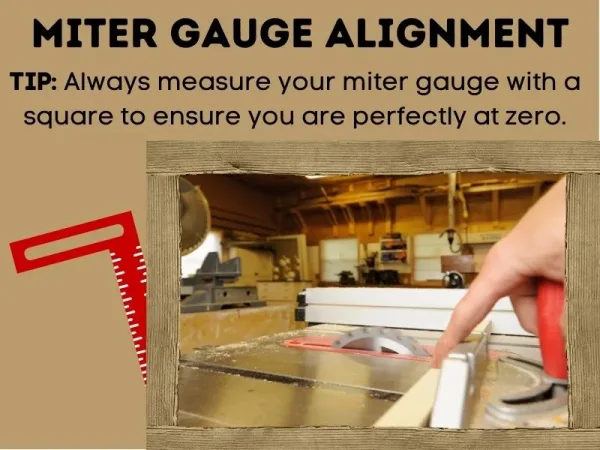

Miter Gauge Alignment

The next item on the list is your miter gauge alignment. This is the piece that uses the slot on your table saw’s table to push the wood through the blade. They typically can rotate for different angles of cuts.

Setting the gauge on zero will get you close to where you need to be for a straight cut, but if you want to have great cuts, it is a good idea to confirm that it is 90 degrees to your blade by using a square.

Fence Alignment

When it comes to the fence on your table saw, there are a couple of measurements you will want to perform. The first is to check that when your table saw fence is locked into position, it is 90 degrees with your table. This is typically not an issue, but it is always a good idea to check and make sure.

The second measurement will be the alignment of the fence to the blade. This can be a bit more difficult to check but can be done with a square with measurements or a precise ruler.

Once the fence is set, measure the distance of a tooth from your fence. Next, rotate the blade so that the same tooth you just measured is on the opposite side of where it originally was. Now measure the distance again, from the tooth to the fence. This number should be the same.

If this measurement is off, but all other measurements have been accurate up to this point, you will want to try to adjust your fence until it sits perfectly parallel to your blade.

Miter Gauge Slot Alignment

Another measurement you can make involves the slot that the miter gauge uses. using the tooth measurement technique that was used for checking fence alignment, could also be utilized here.

Check the distance of a tooth from the miter gauge slot on one end, then rotate the blade and check the distance of the same tooth from the slot again. These numbers should be the same. If there is a difference, look into your owner’s manual and see if there is an adjustment for the table itself. It may need to be adjusted so that the miter gauge slots run parallel to the blade.

Optional Table Saw Sled

If you can’t seem to get everything set correctly, or if you just want to have a quick go-to for making straight cuts without having to do all the measuring every time, it may be beneficial to look into a sled.

There are a ton of resources online that detail how to build a sled for your table saw. This can be a solid choice and a great addition to your workshop if you go this route.

However, even with a sled, you will still need to make sure things are aligned, but it may eliminate having to check miter gauges and fences if you build yours correctly.

Is Your Table Saw Blade Causing You to Not Get a Straight Cut?

If everything is perfectly aligned, but you still can’t get a straight cut, you could be having an issue with the blade itself. There are a few things that could be to blame for this, including: a warped blade, loose blade, damage blade, and even a dirty blade. These are all issues that should be checked to make sure they are not the cause of your issues.

Along with having cuts that aren’t exactly straight, you may experience other symptoms as well if any of these are happening.

Warped Blade

A warped blade can occur for several reasons. It could be from a manufacturer’s defect or even overheating of the blade. If your blade is not flat, it will cause the cuts to vary as you pass the wood through the table saw. If the blade itself does not make straight cuts, then you can expect your wood to exhibit the same behavior.

To diagnose a warped blade, you can get the blade up to speed and then shut it off. While it is still rotating and as it starts to slow down, look at the blade straight on. If the blade is warped, you may notice a wobble in the blade.

It may be subtle and can help if you change the blade with a new one and compare what they look like while they are spinning. If you suspect this is an issue, there are methods to flatten the blade, but my personal preference is just to replace it altogether. If it is still sharp, it can still be useful for things that don’t require high precision.

Loose Blade

If you suspect you have a loose table saw blade, this should be fixed immediately. This is a serious safety concern, as it is a high likelihood of causing kickback or coming loose from the table saw altogether. The first thing to do is to make sure the arbor nut is torqued down properly.

If you still have issues with your blade being loose, you need to look further into the possible cause before continuing to use it. I found a pretty helpful article that takes a look at multiple possible causes. You can check it out here.

Damaged/Dirty Blade

A damaged table saw blade (let’s say bent or broken teeth) will not cut a straight line. It may appear to be straight and may work for most cases, but as soon as you go to put two boards side by side, you will notice gaps and less-than-perfect seams. This could be caused by either a damaged or dirty blade.

These two go hand in hand because they can display a lot of the same symptoms. Along with not having great cuts, you will start to notice some other symptoms as well such as: burning, binding, tear out, and being harder to feed. If this sounds like something you may be dealing with, you can find my other article here, where we take a deeper look at cleaning your table saw blade or replacing it if it is damaged.

Are You Feeding the Board Through the Table Saw Correctly?

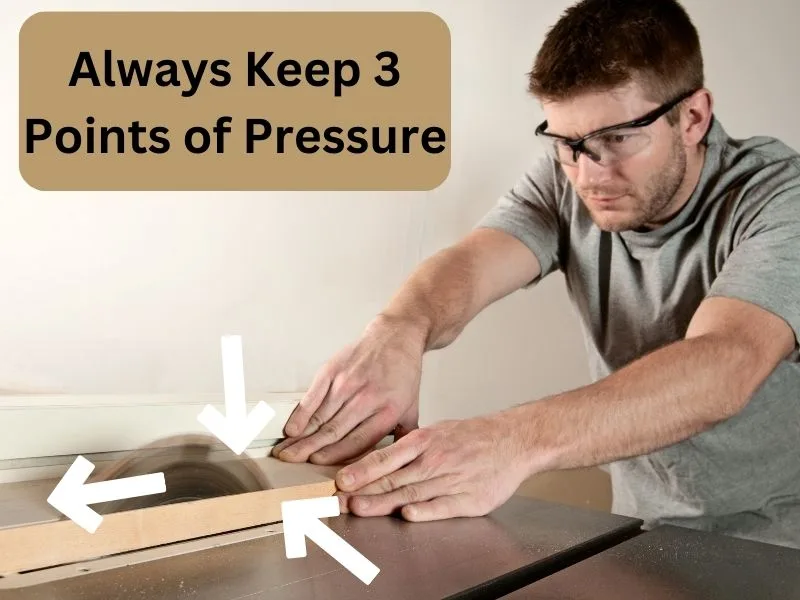

Another possible cause of not having straight cuts on your table saw could be incorrect feeding of the board through the table saw. When you feed a board through a table saw, it needs to be supported correctly, and pressure applied in the correct spots. Failing to do so will lead to out-of-square cuts, could provide a kickback scenario, and be potentially dangerous.

When using the table saw, it is important to apply pressure at a few points. You will want to keep pressure on the board downward on the table, pressure on the wood going into the saw blade, and also pressure on the board into your fence. This will keep the board located and will help make straight cuts straight and add safety to the process.

You will want to avoid applying pressure to the board on the side that has already been cut as this can cause bad cuts or even kickbacks. Visit this article here that I found online, which goes a little bit deeper on some helpful tips for using a table saw correctly and safely.

Conclusion

Hopefully, the information I have provided will help you determine what is causing your table saw to not cut straight and how to fix them. Just to highlight the main points, if your table saw keeps cutting out of square there are a few items you will want to check; your table saw’s alignment, your table saw’s blade condition, and that you are using the correct methods for cutting.